SUPERBA S.A.S. with their headquarters in Mulhouse, France are the global leader in continuous heat-setting process with saturated steam of BCF carpet yarns, SPUN and WOOL blends.

SUPERBA S.A.S. with their headquarters in Mulhouse, France are the global leader in continuous heat-setting process with saturated steam of BCF carpet yarns, SPUN and WOOL blends.

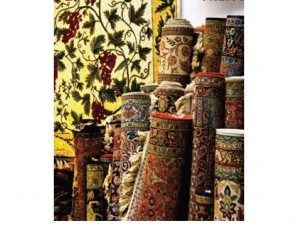

With more than 35 years of experience in the specialized field of high quality tufted and woven carpets, SUPERBA is providing innovative and competitive solutions with complete range of machines, including the TVP3, the latest generation of heat-setting line, together with the friezing machine – MF4 and fully automatic winder – B401, all manufactured in France by SUPERBA.

SUPERBA also provides the LV3 steaming and shrinking lines for heat setting Acrylic yarns, MCD/LA Space-dyeing machines and GREENTEX for artificial turf complete with their range of products for the flooring industry. With high performance, efficiency and being eco-friendly, these lines integrate the latest technologies in term of automation. SUPERBA is having subsidiaries in the USA, in UAE (Dubai) and in CHINA, and 60 representatives all over the world to extend better services to their international customers. With their improved technologies both for heat-setting of carpet yarn and for the texturization in the manufacturing of artificial turf Superba is constantly increasing their interest in the Middle-East market, and especially in the Turkish market. Superba presented again in November for the Domotex Middle East with their representative SAMOTEKS.

Domotex fairs are important exhibition areas for carpet manufacturers from all over the world. This is why, for Superba, Domotex is important since it is an event attended by all the global customers, and thus a very effective way of strengthening our commercial relation with them. Even when SUPERBA thinks that Domotex Hannover is the main exhibition, the relocation of Domotex Middle-East in Istanbul is clearly a good choice. It is important especially for Superba and the Turkish market

Domotex fairs are important exhibition areas for carpet manufacturers from all over the world. This is why, for Superba, Domotex is important since it is an event attended by all the global customers, and thus a very effective way of strengthening our commercial relation with them. Even when SUPERBA thinks that Domotex Hannover is the main exhibition, the relocation of Domotex Middle-East in Istanbul is clearly a good choice. It is important especially for Superba and the Turkish market

With Superba technologies the customers know they are investing in lines that are able to process any type of qualities (BCF fibers) with the same very good results in terms of durability, soft hand touch and quality. Indeed, SUPERBA is known all over the world for being the type of machine required to produce high quality carpet. Furthermore, customers in the carpet field can rely on Superba having more than 35 years of expertise in the domain. Superba has always been present in the carpet fields with Superba machines running on the five continents. However, it is true that in the carpet world U.S.A and Turkey are currently the two main poles and in a second duvar

row, Middle- East and Asian countries.

After record sales in Turkey in 2012, it seems the market is now more active in the USA, because the situation there is back to a slowly growing economy especially for real estate. This leads to some increase of demand for wall to wall carpet and the development of new companies.

One of our important customers in the USA is claiming to use only the best technologies for carpet manufacturing and he has the largest existing number of TVP3 lines installed; they do trust Superba’s materials and technology and this is one of the reasons why SUPERBA is able to sell TVP3 in such a large scale. In contrast, the instability of Middle-East is currently not a positive factor for the business. SUPERBA still maintain very close relation with their customers in Egypt or Syria, where very good business was launched, but because of instability we can feel a significant slowdown.

Fortunately, the Gaziantep area in Turkey is still spared from these troubles, and business continues to be rather active, despite a global decrease in the investments, mainly due to the delay in the opening of the zone 5, and uncertainties of the industrial world. About current technological trends, we can notice the increase in the production of polyester qualities in the market and the use of fine yarn count in carpet manufacturing.

Polypropylene is still a fiber used at a large scale, mainly in Turkey, when Polyamide 6 & 6-6 are still in the run; the treatment with SUPERBA process is known for years as giving to Nylon 6 a very high uniformity of treatment to this delicate fiber, thus avoiding streaks in the final product. It also leads to a high tenacity, thus getting a very high quality yarn required especially for the upmarket wall to wall products. We also observe a recent increase of demand for space-dyed yarn. Space-dyeing is a special type of dyeing where small spots of different colors are applied on the yarn bundle. In the past, such yarns were obtained with a knit-deknit discontinuous process. New technologies have appeared to replace this complex process, bringing much more efficiency and flexibility in the pattern design. SUPERBA has been mastering this technology for years and provide a space-dyeing machine using the highest technology on the market. SUPERBA’ Multi Color Dyeing Machine (MCD/ LA) can spray spots of eight different colors on the yarn in a fully continuous bobbin to bobbin process. The spot length can be as long as desired, but also as short as 15 millimeters, which means a very short application time for the dyestuff. For this yarn dyeing process, SUPERBA is using a special patented linear motion system which is the result of years of research and developments with an amazing opening time for the dyestuff jet lower than 2 milliseconds. This is the kind of innovative features customers are looking for from a machine manufacturer like Superba.

When investing into Superba lines it is not the first cost that has to be taken into consideration: with Superba lines customers get high quality certified machines with an efficiency level generally above 95%, low energy consumption, and they have significant return on investment in a quite short time. On top of that, customers know they will get the support of experts with right production tools, right service, high expertise and knowledge in all carpet related domains. SUPERBA also provide a high level of service with skilled technicians on the field, and OEM spare-parts available at customer’s door: the partnership started with the company BILGE in Gaziantep is a very good example and a great success: in one year, the spare-parts sales have drastically increased due to immediate availability of genuine spare-parts. Customers have underlined that quality, safety and service brought by OEM parts have high added value. Nowadays, customers are no longer only interested in prices of the machines or spare-part but also in know-how, quality and service in global view of the manufacturing and purchasing process.

Tekstil Teknik Dergisi Tekstil Haberleri, Tekstil Sektörü, Tekstil Teknik

Tekstil Teknik Dergisi Tekstil Haberleri, Tekstil Sektörü, Tekstil Teknik