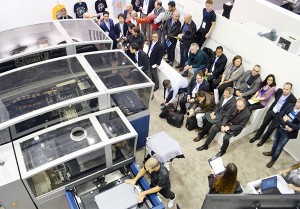

We came together with Kornit Digital in FESPA Eurasia in the last year. We met with Oliver Luedtke who is the Marketing and Business Development Manager of Kornit Digital which continues its innovation in the digital textile printing in ITMA Fair. Luedtke answered our questions about the development by saying ‘ What we do here is not only a Show, we want to enter into the textile industry. In addition to this, I think that we have a significant difference from others.

We came together with Kornit Digital in FESPA Eurasia in the last year. We met with Oliver Luedtke who is the Marketing and Business Development Manager of Kornit Digital which continues its innovation in the digital textile printing in ITMA Fair. Luedtke answered our questions about the development by saying ‘ What we do here is not only a Show, we want to enter into the textile industry. In addition to this, I think that we have a significant difference from others.

What is changed in your business since the last fair?

“Kornit develops at the rate of 35% each year. We also had minimum 50 million dollars costs in the last year. We grow and develop. There is not so much change in the terms of system in the DTG side. We also offer a solution that we called as new ‘giant print solution’ for our Avalanche models. Much bigger parts can be cutted such as 1 meter to 1,20 meter. Allergo was a much better product in last year but now it became a commercial product. We performed a configuration which is open for the order and in a certain number. We performed a configuration in Berlin. We have a new configuration in Portugal. This product has an attraction in Europe. The Vulcan that you can see here is our new main product… It is a new concept that can make printing directly to the cloth… We seperated the loading and unloading process in Vulcan. It has been handled by two person, our previous models have been managed always by a single operator. This machine is a quite interesting machine with the high production amount. If you make production over 500 pc in a year, this machine will be attractive for you. The inkjet that we used before is a little bit

sticky but our new inkjet provides completely a sharp surface. The print quality is alse developed. We do not take any order now.’

You are know with your quality and speed in the market. What are your expectations from the market?

“The difference between Europe and Turkey is that the costs in Turkey are much lower. The costs of the employees are really so low… The production amount in Europe is not same as in Turkey, therefore to use this product in e-trade business in Turkey will provide a significant solution for the textile industry.’

What is the most important thing for your customers, the inkjet, swage block material, etc?

“Our customers who use our products achieve success. For example, a customer of us who uses Allegro is quite successful. They develop globally. They did not catch this success with an other system because the use of Allegro is very easy. The machine has not much demands. The simplicity in the use of the product is the most important factor because the users want to focus on the productivity. They do not want to waste their time by using the old type technology. The use and installation simplicity makes the machine more attractive.”

When will we see the digital textile in our clothes?

“This technology has been produced only for this purpose. All clothes that you see here in the hangers have been printed in Allegro. However, there is not so much print service provider who use this technology. I am sure that there will be distributors who will provide this service in the next days. The clothes which are person-based measurement and printed will come to the light. What we do here is not only a Show, we also want to enter to textile industry. I also think that we have a significant difference from others. An other important solution that we showed in ITMA is our software. In fact this is a solution shows that we are not only a equipment manufacturer. This design program with simulation which makes the production to reduce to one, provides the cloth will be sent to the printing after the designer designed the cloth and after this has been simulated in the screen in accordance with the required measurement. Patterns which are drawn by the designer in the system which works together with Zund, have been cut as digitally in Zund after the printing and became ready for the sewing. It means that. The final consumer can make a cloth order by applying his /her own cloth design or the patterns that the consumer chose by himself/ herself to the designer’s design. The digital print shows a fast development in the textile. This fast development will also correspond a significant increase in the share of market in a short span of time.”

Tekstil Teknik Dergisi Tekstil Haberleri, Tekstil Sektörü, Tekstil Teknik

Tekstil Teknik Dergisi Tekstil Haberleri, Tekstil Sektörü, Tekstil Teknik