Dr. Emel Alaybeyoğlu, Ege University, The Faculty of Textile Engineering, Bornova, Izmir, Turkey

Dr. Emel Alaybeyoğlu, Ege University, The Faculty of Textile Engineering, Bornova, Izmir, Turkey

Prof. Dr. Ayşegül Körlü, Ege University, The Faculty of Textile Engineering, Bornova, Izmir, Turkey

Prof. Dr. Kerim Duran, Ege University, The Faculty of Textile Engineering, Bornova, Izmir, Turkey

Abstract

It is clearly seen that sustainable production is the key factor in textile industry along with other industries. Fibers which are produced by renewable sources have significant role in textile industry. A new generic class of synthetic fiber, PLA (Polylactic acid) is increasingly important raw material in recent years in terms of environmental responsibility for production processes and is with obtained renewable resources [1]. Various properties of PLA and its mixtures in terms of fiber characteristics may make them attractive in commercial sectors. This article mainly aims to investigate and present some specifications of mixtures of PLA fibre with commonly using fibers (Lyocell and Cotton) in Textile Industry since PLA is offered new generation sustainable synthetic fiber instead of PES fiber. Hydrophilicity, water retention power, antibacterial activity, whiteness and yellowness degree of PLA fibers and their blends with Cotton and Lyocell fibers were investigated. In addition, ATR- FTIR (Fourier Transform Infrared Spectroscopy-Attenuated Total Reflectance) spectra of PLA, Lyocell and Cotton fibers were examined to understand studied fibre specifications well in this study.

Key Words: PLA Fiber, Antibacterial Activity, Hydrophilicity, ATR-FTIR, Whiteness and Yellowness degree. Corresponding Author: Emel Alaybeyoğlu.

1.Introduction

It becomes inevitable that new textile provisions play a supportive role in world’s developing conditions. Increasing environmental pollution, decreasing oil and water reserves, thus increasing prices of oil sourced fibers as well as rising temperatures due to global warming are evidences of the need for new generation fibers and expanding their areas of use. Lyocell is a new generation cellulosic fiber which was first produced in 1980s. It was environmentally responsible for a process and utilized renewable resources as its raw materials. PLA fiber which was developed in recent years is a new generic class of synthetic fibers and is becoming increasingly attractive due to the need for protection of the environment thanks to its ability to be manufactured from sustainable resources [2, 3]. Lyocell is a cellulosic fiber derived from wood pulp made by a solvent spinning process. The wood pulp is dissolved in a solution of ‘amine oxide’ (usually N-methylmorpholine-N-oxide). The solution is spun into fibers and passed through a washing process. More than 99.5% of the solvent was recovered in manufacturing process. The solvent is non-toxic and all residues are non-hazardous. It is directly dissolved in an organic solvent that is differentiated lyocell from other regenerated cellulosic fibers such as viscose. Lyocell is bio-degradable and absorbent. It has high values in both wet and dry strength in contrast to viscose fibers. Lyocell has propensity to fibrillate when fiber is exposed to friction in wet conditions. Fibrillation behavior of fiber makes it attractive in producing fabrics which have excellent hand feeling and aesthetic characteristics [2]

PLA (Polylactic acid) is linear aliphatic thermoplastic polyester derived from 100% renewable resources such as corn, sugar beet and etc. PLA fiber is 100% compostable at the end of its life and its life cycle potentially decreases Earth’s carbon dioxide level. PLA fibers are called the new generic class of synthetic fibers. The new approach is becoming increasingly important for protecting the environment and manufacturing products from sustainable resources. Carbon dioxide and water found in the atmosphere are converted into starch through photosynthesis of plant cells. Starch is extracted from plants and converted to a fermentable sugar by enzymatic hydrolysis. Fermentable sugars are converted to lactic acid through fermentation. Polymer is formed in two ways; by condensation of lactic acid or through a ring opening process. PLA fiber is produced by melt-spinning process [3]. Anti- bacterial products are leading textile products through protection of health, personal hygiene and comfort. Use of these products is important especially in hospital garments [4, 5]. Working conditions provide suitable atmosphere for fast reproduction of microorganisms. Microorganisms are in human body, in air, on soil and everywhere. When suitable conditions are provided, they reproduce rapidly. Microorganisms lead to deterioration of products, generating stains and undesirable odors; spread of microorganisms in crowded environments can also cause allergic reactions which can result in infections in human body [4, 5]. It should keep nonpathogenic microorganisms under control not only for undesirable odor and appearance, but also for their dangerous effects on human health through inhibition of reproduced pathogenic microorganisms [6].

Knitted fabrics composed of mixtures of polylactic acid with Lyocell and Cotton fibers were examined in this study. Fabrics which are generated from different mixtures of these fibers were tested for their some properties. Antibacterial activity, hydrophilicity and water retention power were evaluated with their fabric weights. Also, whiteness and yellowness values of fabrics were examined. Furthermore, Attenuated Total Reflectance- Fourier Transform Infrared Spectroscopy (ATR-FT-IR) was used for analyzing material structure. By this technique, a lot of information was obtained on molecular regions which are expected to identify the chemical environment of fabrics.

2. Material and Method

2.1 Material

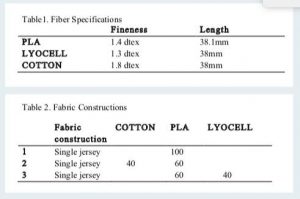

Fibers whose characteristics are given below were used in this study. (Table 1)

2.2 Method

100% Lyocell and 100% Cotton knitted fabrics having thickness of 30/1 were also used only to compare with ATR-FTIR diagrams. Antibacterial properties of fabrics were tested according to AATCC-100. The AATCC-100 test method is a quantitative analysis for the evaluation of antibacterial activity. Test bacteria Staphylococcus aureus (Gram positive organism) was used in this study for evaluation of antibacterial efficiency [7]. Hydrophilic degree of fibers was determined through the test standard DIN 53924. A 3 cm wide and 25 cm long strip fabric was suspended vertically. Lower end of it was immersed in a beaker which contained potassium chromate solution by 1%. Solution height on the fabric was measured at 10, 30, 60, 90 seconds, 5 and 10 minutes [8]. Measuring method of water retention power of samples was explained below. Dry weight (0.50 mg) of fabrics

was compared to their wet weight. First, test fabrics were kept for 30 minutes in a beaker which fully contained distilled water. Second, they were put in funnels for 30 minutes. Third, test fabrics were squeezed on laboratory type centrifuge for 5000 cycles and 15 minutes. Finally, fabric pieces were weighed by precision balance and the difference between dry and wet weight was calculated [9, 10]. Whiteness and yellowness values of fabrics

were measured by using spectrophotometer (UltrascanPro) according to WI CIE (D65/10) and YI E313(D65/10), respectively. ATR-FTIR of knitted fabrics was carried out with Perkin Elmer Spectrum 100. Scanning range of the spectrophotometer was between 4000 and 650 cm¯¹. All tests were repeated for 3 times for each of the methods mentioned above.

3.Result and Discussions

Water retention power of fabrics is shown in table 3. Weights and densities of fabrics are also indicated at the same table.

Water retention power of fabrics is shown in table 3. Weights and densities of fabrics are also indicated at the same table.

While water retention power of 100% PLA knitted fabric was 350%, it was 369% on fabric composed of 60 PLA% 40% cotton, and 383% on 60PLA% 40% lyocell. It appears that 40% Lyocell fiber ratio in fabric construction increased water holding capacity although it has lower fabric weight. Lyocell fiber was more efficient than cotton fiber in this respect. Test results of hydrophilic characteristics of fabrics in 10-30-60-90 seconds, and 5 and 10 minutes are given in table 4.

Hydrophilic specifications of designed fabrics were tested and it was found out that fabric type mixed with cotton was not hydrophilic due to layer of fat and wax on raw cotton fiber. Pre-treatments processes were not applied to tested fabrics for removing the layer. This characteristic was obstructed by hydrophilicity. Hydrophilic value of 100%PLA fabric was 3.7 cm in 90s. Hydrophilic characteristic of 60% PLA 40% lyocell knitted fabric was measured as 4.06 cm in 90s. It was seen that Lyocell fiber was more hydrophilic than PLA fiber. Sorption properties (hydrophilicity, water retention power and etc.) of fibers are determined according to size and orientation of amorphous regions, void fracture (diameter, volume, and specific inner surface) and their surface interaction properties. The primary-wall of cotton fibers is composed of cellulose, fats, waxes, pectic and proteic substances. Pure cellulose is located in the secondary wall. Crystalline and amorphous regions in cellulose macromolecules alternate along fibrils. During pretreatment procedures, e.g. alkaline treatments, natural cellulose (cellulose I) converts into cellulose II; this is also characteristic for regenerated cellulose fibers such as lyocell. Owing to fats, waxes and others in primary-wall, raw cotton fibers have rather hydrophobic characteristics. As expected, lyocell fiber has better sorption properties. In fact, chemical structure of Lyocell is similar to cotton apart from the length of cellulose molecules. While degree of polymerization of cotton fiber is 2000, Lyocell is around 600–800. In both fibers, cellulose molecules consist of crystalline and amorphous regions. The crystallinity rate of cotton is about 80% and the rate of Lyocell is 60%. The chain orientation is very high in cotton, while rather lower in Lyocell. This information explained why Lyocell sorption properties were found to be better than others [11, 12, 14]. Crystallization behavior of PLA depends on molecular weight and chemical structure. Chemical structure of PLA is controlled by the polymerization with D-lactide, L-lactide, D, and L-lactide or meso lactide. Extent of crystallinity greatly depends on polymerization conditions and amount of meso-, D-lactide, or L-lactide. Polymers with high L-lactide units produce crystalline polymers while polymers consist of the higher D-lactide units (>15%) are more amorphous. It is possible to obtain a wide range of molecular weights and a great variety of D-lactic units in polymer chemical structure. Thus, fiber properties can be changed by amorphous area ratio. These changes affect melting behavior, thermal properties, barrier properties, and ductility of fibers. Sorption properties of PLA were found to be better than raw cotton fiber because of the amorphous region in its structure, while PLA sorption behavior was lower than lyocell fiber [2, 3, 13]. Antibacterial activity of pure PLA control fabric was compared to Cotton and Lyocell blended fabrics’s activities. Antibacterial activity performance of 100% PLA fabric according to AATCC147 was found negative for both gram-positive S.auresus and gram-negative K.pneumoniae bacterias in Ph.D. thesis. by Emel Alay. [15] On the other hand, although it was not achieved high performance on S.auresus bacteria by only pure fibre, it showed supportive role in mixtures of worked in terms of antibacterial activity. Antibacterial activity of 100% PLA against Escherichia coli (gram-negative bacteria) was found to be low (35% reduction) in Phd study by Emel Alay as well [15]. Consequently, it has seen that PLA fibre effected to reproducing of gram positive bacterias. Therefore the study was carried out only on gram-positive S.aureus bacteria.

The results are given concerning Staphylococcus aureus according to the AATCC-100 test standard in table 5 below.

Antibacterial activity of 100% PLA knitted fabric was measured as reduction of bacterial growth by 88%. When fabric was designed as 40% Cotton 60%PLA, antibacterial activity dropped to 5.97%. When it comes to mixed PLA fiber with lyocell fiber, the fabric which was composed of 60% PLA 40% Lyocell, had an antibacterial activity of 43.28%. This indicates that lyocell ratio of designed fabric caused reduction in antibacterial efficiency, but not as much as cotton fiber. PLA fibers do not have antibacterial activity intrinsically. However, they do not provide an environment for bacterial growth by their nature as mentioned in the literature 3. This is supported by decrease of antibacterial activity by 88% on 100%PLA fabric. The inherent properties of textile fibers provide suitable environment for growth of micro-organisms. Structures and chemical processes induce growth of microbes. Some important characteristics such as hydrophilicity of fabrics, fiber content and composition of fabric affect adherence. Large numbers of bacterial species deteriorate different types of textile materials by feeding on them or by easily hydrolyzing certain bonds in them. Natural fabrics like cotton having cellulose as key ingredient are affected by several kinds of bacteria. They are prone to microbial decomposition as these fibers have chemical bonds which can be readily hydrolyzed by microorganisms contrary to synthetic fibers. Products such as starch, protein derivatives, fats and oils used in finishing of textiles can also support microbial growth in natural textile materials. While synthetic fiber by itself does not promote microbial growth, compounds such as lubricant and spinning oils used in finishing of textiles provide sufficient nutrient for mild surface growth of microorganisms. As it was seen from the results of antibacterial activity of tested fabrics, antibacterial efficiencies of all fabrics were not found at excellent level. In addition, Lyocell fibers consist of hydrophilic nanofibrous structure, and this structure ensures excellent absorption and releases moisture more than cotton fiber. Lyocell fibers do not keep any water on fiber surface like cotton fiber. So, they do not take charge in bacterial growth as cotton fiber [2, 3, 16, 17] .

fabric was designed as 40% Cotton 60%PLA, antibacterial activity dropped to 5.97%. When it comes to mixed PLA fiber with lyocell fiber, the fabric which was composed of 60% PLA 40% Lyocell, had an antibacterial activity of 43.28%. This indicates that lyocell ratio of designed fabric caused reduction in antibacterial efficiency, but not as much as cotton fiber. PLA fibers do not have antibacterial activity intrinsically. However, they do not provide an environment for bacterial growth by their nature as mentioned in the literature 3. This is supported by decrease of antibacterial activity by 88% on 100%PLA fabric. The inherent properties of textile fibers provide suitable environment for growth of micro-organisms. Structures and chemical processes induce growth of microbes. Some important characteristics such as hydrophilicity of fabrics, fiber content and composition of fabric affect adherence. Large numbers of bacterial species deteriorate different types of textile materials by feeding on them or by easily hydrolyzing certain bonds in them. Natural fabrics like cotton having cellulose as key ingredient are affected by several kinds of bacteria. They are prone to microbial decomposition as these fibers have chemical bonds which can be readily hydrolyzed by microorganisms contrary to synthetic fibers. Products such as starch, protein derivatives, fats and oils used in finishing of textiles can also support microbial growth in natural textile materials. While synthetic fiber by itself does not promote microbial growth, compounds such as lubricant and spinning oils used in finishing of textiles provide sufficient nutrient for mild surface growth of microorganisms. As it was seen from the results of antibacterial activity of tested fabrics, antibacterial efficiencies of all fabrics were not found at excellent level. In addition, Lyocell fibers consist of hydrophilic nanofibrous structure, and this structure ensures excellent absorption and releases moisture more than cotton fiber. Lyocell fibers do not keep any water on fiber surface like cotton fiber. So, they do not take charge in bacterial growth as cotton fiber [2, 3, 16, 17] .

Due to chemical characteristic of fiber, bacteria multiplied easily on fabric. The rate of cotton fiber in fabric provided a suitable environment for bacterial growth as can be seen in table 5 above.

Whiteness and yellowness values measured by spectrophotometer of fabrics are also listed in table 6 above.

Fabric construction having the highest whiteness value was 60% PLA 40% Lyocell knitted fabric. There was a small difference compared to 100% PLA fabric. But 60% PLA 40% Cotton knitted fabric has the lowest ratio and yellow nuance. The reason for this is the cotton fiber which was used in the construction because of natural fiber color.

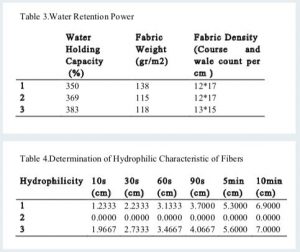

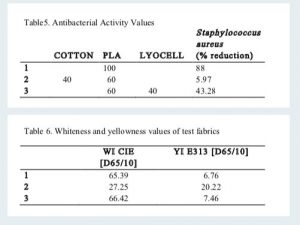

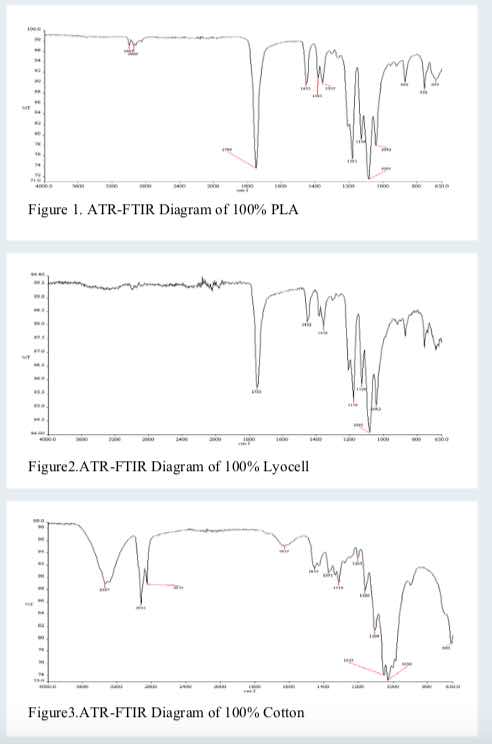

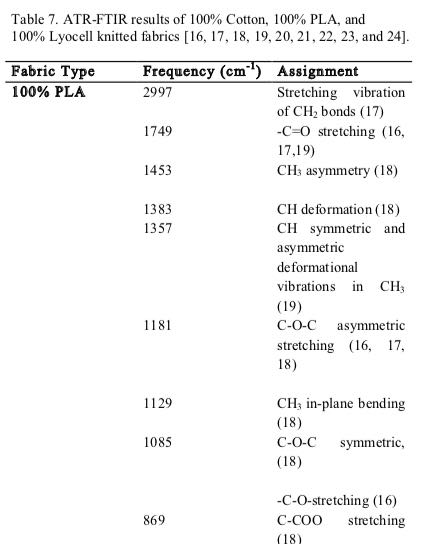

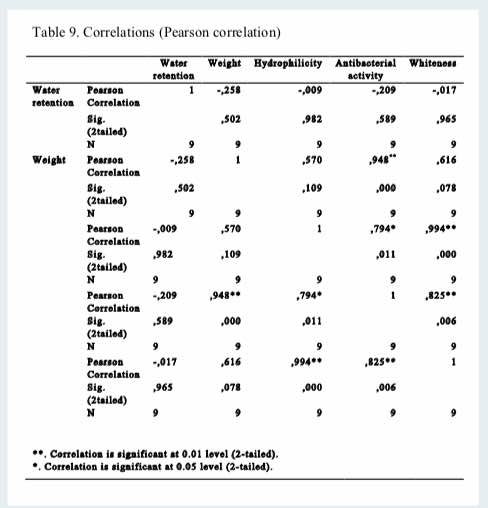

ATR-FTIR of knitted fabrics was carried out with Perkin Elmer Spectrum 100. ATR-FTIR diagrams of 100% PLA, 100% Cotton, and 100% Lyocell are shown in fig1, fig2 and fig3.

ATR-FTIR of knitted fabrics was carried out with Perkin Elmer Spectrum 100. ATR-FTIR diagrams of 100% PLA, 100% Cotton, and 100% Lyocell are shown in fig1, fig2 and fig3.

Figure 1 shows ATR-FTIR spectra of 100% PLA. The peak band wave numbers relate to hydrogen bonding of PLA. It is already known that PLA has a strong carbonyl stretching absorption at about 1749 cm¯¹. It was indicated that the peaks are at about 1181, 1085cm-1 for (–C–O–C) PLA. The peak assignments and corresponding positions of 100% PLA are given in table 7 [18, 19, 20, 21].

ATR-FTIR spectrum of 100% Cotton knitted fabric shown in Fig.3 revealed peaks attributed to Cellulose I. The wide peak at 3337 cm¯¹ described the stretching motion of intra-molecular hydrogen bonds which is related to cellulose I. The intensity observed at the peak of 1627 cm¯¹ is related to the adsorbed moisture (H2O). Important features of the spectra are shown in table 7 [21, 22, 23, 24]. Figure 2 shows that 100% Lyocell knitted fabric as confirmed by ATR-FTIR spectra is around the wave number of 1100 cm¯¹. Other frequency bands and peaks of great intensity for lyocell are also listed in table 7 [25, 26].

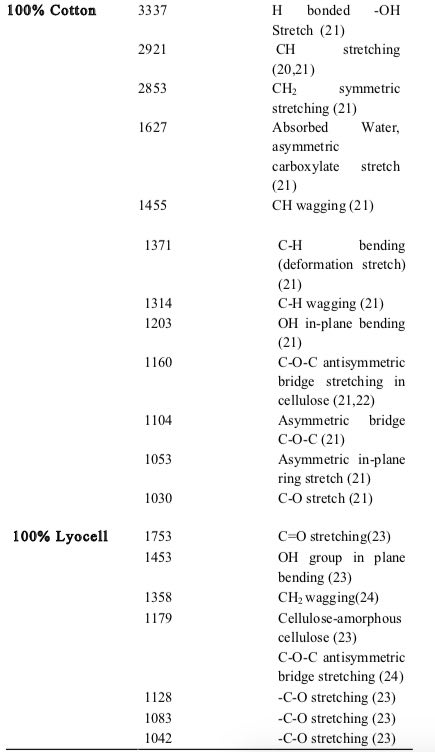

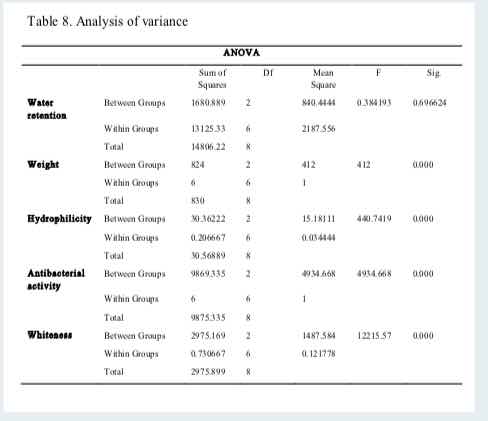

Infrared spectra of all fabrics indicate that there were distinguishable peaks. Deterministic peaks of designed fabrics are listed in table 7 below. Statistical analysis of results was performed in SPSS by applying analysis of variance (Table 8). In addition, in order to check the effects of parameters on each other, Pearson correlation tests were performed (Table 9). Effect of fabric type on antibacterial activity, whiteness and hydrophilicity was significant, but it was unremarkable on water retention power.

A correlation between hydrophilicity and antibacterial activity is seen in statistical analysis. Accordingly, effect of hydrophilic characteristic was significant on antibacterial activity (oc =0.05). Water retention power was not efficient on antibacterial activity since all fabrics were immersed into water, kept in funnels and squeezed with water for water retention power test. Water was almost forced into fabric owing to test pattern, and this test had longer processing time compared to hydrophilicity test standard. Therefore, while results of hydrophilicity were different, results of water retention power were almost similar in the study.

4. Conclusions

Different from many previous researches, antibacterial characteristics of PLA fibers and its blends with Lyocell and Cotton fibers were investigated in this study without use of any additives such as silver, chitosan, etc. Besides, It is seen that PLA reinforced composites are subjected to many articles on academic and commercial areas [27]. But there are limited investigations on characterization of PLA mixtures

knitted fabrics. This article present some properties of hybrid knitted fabrics. ATR-FTIR was used for analyzing chemical structure of fibers in order to clarify some of the characteristics of designed fabrics which were investigated in this study. Chemical bonds and molecular regions of fibers were checked and linked with other properties through ATR FTIR analysis. Finally, it was seen that while there was more antibacterial efficiency since bacteria couldn’t destroy strong carbonyl stretching bonds in PLA, they could grow easily in Cotton and Lyocell fabrics owing to weak hydrogen bonds. Similar effect of chemical structure in terms of hydrophilicity and water retention power should be taken into consideration. It was found out that knitted fabrics composed of PLA and its mixtures with Lyocell and Cotton fibers had insufficient level of antibacterial activity. Hydrophilic characteristics of PLA/Lyocell fabric was confirmed to show high value. In addition, water retention power of the fabric was sufficient to take into account other raw materials. Furthermore, when their whiteness values were checked, it was seen that they had enough level of whiteness. These results support optimization of textile finishing processes of PLA  mixtures fabrics for future studies. As well as many advantages of PLA fiber in term of environmentally friendly new generation fiber, it is a hydrophobic fibre and has many disadvantages especially at pre-treatment processes in textile finishing. The results of this study shows Lyocell and Cotton mixtures how much increase or decrease of pure PLA fiber specifications.

mixtures fabrics for future studies. As well as many advantages of PLA fiber in term of environmentally friendly new generation fiber, it is a hydrophobic fibre and has many disadvantages especially at pre-treatment processes in textile finishing. The results of this study shows Lyocell and Cotton mixtures how much increase or decrease of pure PLA fiber specifications.

References: 1.Shanmugasundaram O. Lakshmanan and Guruprasad Raghavendran, Regenerated Sustainable Fibres, Sustainable Innovationsin Textile Fibres, Textile Science and Clothing Technology, Hong Kong,31,(2018) 2. White P., Hayhurst M., Taylor J. & Slater A., Biodeg. and Sust. Fibres, Edited by Richard Blackburn, University of Leeds, Woodhead Publising Limited,Cambrigde England, Chapter 5, 157, (2005) 3. Farington D.W.,  Lunt J., Davies S. & Blackburn R. S., Biodeg. and Sust. Fibres, Edited by Richard Blackburn, University of Leeds, Woodhead Publising Limited,Cambrigde England, Chapter 6,191, (2005) 4. Dattilo P.P.Jr., King M.W., Cassil N.L. & Leung J.C.,J. of Text. and Apparel, Tech. and Manag., 2(2),1, (2002) 5.Gao Y. & Cranston R, Text. Res. J., 78(1), 60, (2008) 6.Supuren G., Kanat Z.E., Cay A. &Tarakcıoglu I.,Teks. ve Konf.,16(2), 80, (2006) 7. AATCC Test Method 100-2004’’ , Antibacterial finishes on textile materials: Assessment of. AATCC Technical Manual’’, American Ass. of Text. Chem. and Colorists, Research Triangle Park, NC, (2005) 8. DIN 53924, Testing of textiles-Velocity of soaking water of textile fabrics (method by determining the rising height), Standard by Deutsches Institut Fur Normung E.V.(German National Standard),( 1997) 9. DIN 53814, Testing of textiles; determination of water retention power of fibres and yarn cuttings, Standard by Deutsches Institut Fur Normung E.V.(German National Standard), (1974) 10. Can C.,’’Zeolit Mineralinin Tekstil Terbiyesinde Kullanım Olanaklarının Araştırılması’’ Ege Universitesi, Fen Bilimleri Enstitüsü, Doktora Tezi, 53, (2012) 11. Kreze T., Stana-Kleinschek K. & Ribitsch V., Lenzinger Berichte, 80, 28, (2001) 12.Strnad S., Sauperl O. & Fras-Zemljic L., Biopolym., Edited by Magdy Elnashar, 181, (2010) 13.Garlotta D., J. of Polym. and the Environment, 9( 2), 63,(2002) 14. Mak C. M., Yuen C. W. M., Ku S. K. A. &Kan C. W.,The J. of The Text. Inst., 97(6), 533, (2006) 15. Alay, E., Improved of Biodegradable, Antibacterial, Odor Resistant Knitted Fabrics, Doctor of Philosophy, Ege University, Graduate School of Natural and Applied Sciences, Textile Technologies, (2016) 16. Bajpai V., Bajpai S., Jha1 M.K., Dey A., & Ghosh S., J.Environ, Res. Edu., 5( 3), 669, (2011) 17. Boryo D.E.A., The Int. J. of Eng. And Sci. (IJES), 2 (8),9, (2013) 18. X.W. Yuan, D. Liu, A.J. Easteal, D. Bhattacharyya & J. Li, Proceedings, iccmcentral, Biomedical Aplications,,(2010) 19. Baig G.A, Indian J. of Fibre &Text. Res.,38, 22, (2013) 20. Hossain K.M.Z, Parsons A.J., Rudd C.D., Ahmed I., &Thieleman W., European Polym. J., 53 ,270, (2014) 21. Pamula E.,Blazewicz M.,Paluszkiewicz C., &Dobrzynski P.,J. of Moleculer Struc., 596 ,69, (2001) 22. Garside P. & Wyeth P., Studies in Conservation, 48(4), 269, (2003) 23.Dave H., Ledwani L., Chandwani N., Chauhan N., & Nema S.K., The J. of The Text. Inst., 105( 6), 586, (2014) 24. Liu Y., Materials, 6, 299, (2013) 25. Kaimouz A.W., An Investigation of the Printing Process for Lyocell and Cotton Fibers Using Inkjet Technology, Doctor of Philosophy,Heriot-Watt University,The School of Textile and Design, 177, (2010) 26.Ozturk H.B., Ehrhardt A., Vu-Manh H., Oksanen T., Siroká B., Suurnakki A., & Bechtold T., Fibres & Text. in Eastern Europe, 19( 4) , 87, (2011) 27.Behnaz Baghaei, Mikael Skrifvars, Characterisation of polylactic acid biocomposites made from prepregs composed of woven polylactic acid/hemp–Lyocell hybrid yarn fabrics, Composites: Part A, 81, 139, (2016)

Lunt J., Davies S. & Blackburn R. S., Biodeg. and Sust. Fibres, Edited by Richard Blackburn, University of Leeds, Woodhead Publising Limited,Cambrigde England, Chapter 6,191, (2005) 4. Dattilo P.P.Jr., King M.W., Cassil N.L. & Leung J.C.,J. of Text. and Apparel, Tech. and Manag., 2(2),1, (2002) 5.Gao Y. & Cranston R, Text. Res. J., 78(1), 60, (2008) 6.Supuren G., Kanat Z.E., Cay A. &Tarakcıoglu I.,Teks. ve Konf.,16(2), 80, (2006) 7. AATCC Test Method 100-2004’’ , Antibacterial finishes on textile materials: Assessment of. AATCC Technical Manual’’, American Ass. of Text. Chem. and Colorists, Research Triangle Park, NC, (2005) 8. DIN 53924, Testing of textiles-Velocity of soaking water of textile fabrics (method by determining the rising height), Standard by Deutsches Institut Fur Normung E.V.(German National Standard),( 1997) 9. DIN 53814, Testing of textiles; determination of water retention power of fibres and yarn cuttings, Standard by Deutsches Institut Fur Normung E.V.(German National Standard), (1974) 10. Can C.,’’Zeolit Mineralinin Tekstil Terbiyesinde Kullanım Olanaklarının Araştırılması’’ Ege Universitesi, Fen Bilimleri Enstitüsü, Doktora Tezi, 53, (2012) 11. Kreze T., Stana-Kleinschek K. & Ribitsch V., Lenzinger Berichte, 80, 28, (2001) 12.Strnad S., Sauperl O. & Fras-Zemljic L., Biopolym., Edited by Magdy Elnashar, 181, (2010) 13.Garlotta D., J. of Polym. and the Environment, 9( 2), 63,(2002) 14. Mak C. M., Yuen C. W. M., Ku S. K. A. &Kan C. W.,The J. of The Text. Inst., 97(6), 533, (2006) 15. Alay, E., Improved of Biodegradable, Antibacterial, Odor Resistant Knitted Fabrics, Doctor of Philosophy, Ege University, Graduate School of Natural and Applied Sciences, Textile Technologies, (2016) 16. Bajpai V., Bajpai S., Jha1 M.K., Dey A., & Ghosh S., J.Environ, Res. Edu., 5( 3), 669, (2011) 17. Boryo D.E.A., The Int. J. of Eng. And Sci. (IJES), 2 (8),9, (2013) 18. X.W. Yuan, D. Liu, A.J. Easteal, D. Bhattacharyya & J. Li, Proceedings, iccmcentral, Biomedical Aplications,,(2010) 19. Baig G.A, Indian J. of Fibre &Text. Res.,38, 22, (2013) 20. Hossain K.M.Z, Parsons A.J., Rudd C.D., Ahmed I., &Thieleman W., European Polym. J., 53 ,270, (2014) 21. Pamula E.,Blazewicz M.,Paluszkiewicz C., &Dobrzynski P.,J. of Moleculer Struc., 596 ,69, (2001) 22. Garside P. & Wyeth P., Studies in Conservation, 48(4), 269, (2003) 23.Dave H., Ledwani L., Chandwani N., Chauhan N., & Nema S.K., The J. of The Text. Inst., 105( 6), 586, (2014) 24. Liu Y., Materials, 6, 299, (2013) 25. Kaimouz A.W., An Investigation of the Printing Process for Lyocell and Cotton Fibers Using Inkjet Technology, Doctor of Philosophy,Heriot-Watt University,The School of Textile and Design, 177, (2010) 26.Ozturk H.B., Ehrhardt A., Vu-Manh H., Oksanen T., Siroká B., Suurnakki A., & Bechtold T., Fibres & Text. in Eastern Europe, 19( 4) , 87, (2011) 27.Behnaz Baghaei, Mikael Skrifvars, Characterisation of polylactic acid biocomposites made from prepregs composed of woven polylactic acid/hemp–Lyocell hybrid yarn fabrics, Composites: Part A, 81, 139, (2016)