Çağatay SÜMER / Production Manager

“This year we exhibited our latest technology machines that we used as Mersan Machinery in ITMA Barcelona. This fair was very productive in terms of presenting our innovations for the sector. At the ITMA Barcelona Fair, we introduced our customers and visitors to the chain, felt sanforizing machine and rubber blanket sanforizing machine for open width knitted fabrics and the gas machine for open knitted woven fabrics.

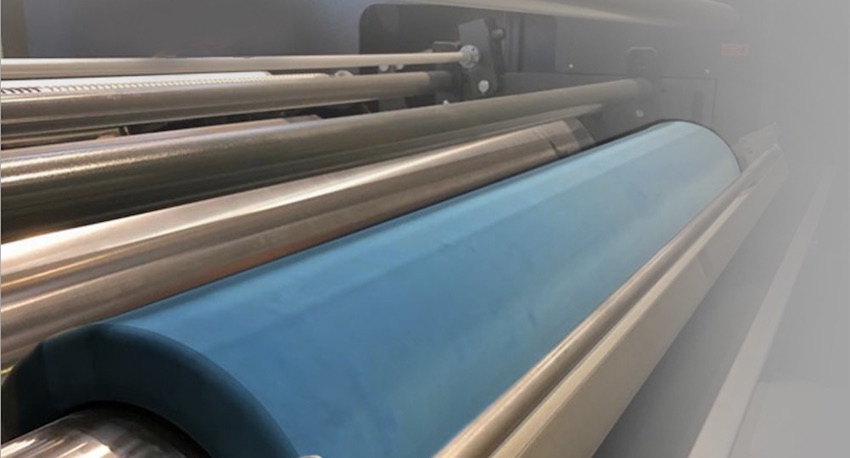

Our open width sanforizing machine, which is developed for fixing in size and giving perfect touch to the fabric, provides high production speed and optimum fabric quality while guaranteeing the desired shrinkage values in the fabric by providing the desired smooth surface in knitted fabrics.

Especially because of the design of our newly developed rubber blanket sanfor machine, it gives extra brightness, extra touch and extra image and makes it different from other fabrics. Gas for knitted and woven fabrics is the outer surface treatment which improves the appearance and improves the subsequent process properties. The same applies to the inner surface of the fabric. It is the cleaning process by burning the excess fibers on the fabric thanks to a continuous flame band thanks to the mixture of air and gas coming out from two parallel water-cooled burners.

At the same time, the gassing machine provides the healthiest process for rotation printing and part printing, recovers from fibers on fabric. This improves print quality and reduces waste. The energy, water, time and chemicals are saved. ITMA is always a different excitement for us. Our expectation from ITMA fairs is to connect with the masses that will increase the export potential of our country. Our goal is to win new customers, of course, and to ensure that the information necessary for the introduction and use of new technologies that we bring to our sector and our country reaches the experts.”