The first “Linked Motion Control” warp feed system from CREALET AG will be delivered to INOBELT in Germany.

INOBELT, a company in the fields of weaving preparation, weaving, braiding and making-up, produces high-quality belts, tapes, cords and ropes for personal protective equipment, technical applications and roller shutter belts (https://www.inobelt.de).

INOBELT, a company in the fields of weaving preparation, weaving, braiding and making-up, produces high-quality belts, tapes, cords and ropes for personal protective equipment, technical applications and roller shutter belts (https://www.inobelt.de).

These are produced according to customer requirements and technical specifications. INOBELT also develops new products together with its customers. The reason for purchasing the new warp thread feeding system is the increased demand for INOBELT products.

What is “Linked Motion Control”?

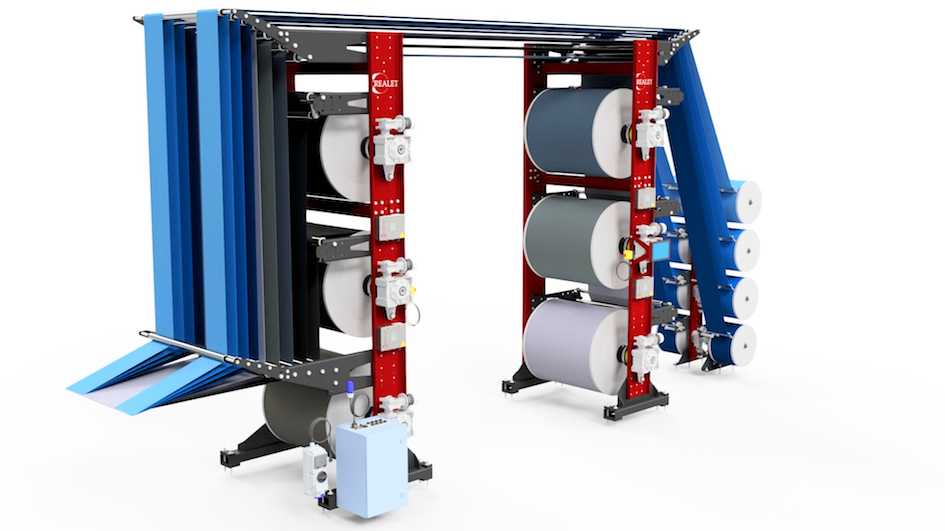

“Linked Motion Control” is the name given to a warp feed system consisting of several warp beams and aPC-based control technology.

The warp running time can be doubled by using 14 warp beams. It massively reduces the frequency of warp beam changes and increases the efficiency of the ribbon weaving machine.

The directly measured yarn tension replaces the adjustment of the warp tension by means of springs. Moreover, the desired warp tension for each beam can be entered directly into the control system.

The direct measurement of the warp tension serves to control the warp beam motors and enables to display the set and actual thread tension on the monitor.

Prepared for Future Applications

We are proud to be able to supply this new warp feed system to a long-time customer in Germany for the first time. The warp feed system is designed for the current technical requirements but is also intended for future applications in the field of Industry 4.0.

With this investment, INOBELT is taking a giant step into the future.